fiber desiccant

Product requirements

Use desiccant?

During the packaging or storage and transportation of the product, the moisture in the air will invisibly penetrate into the product, resulting in product decolorization, deformation, peculiar smell, mildew, corrosion, etc.dampinjuries.

Product Description

Product Parameters

[product name] film type fiber desiccant

[product raw material] plant fiber

[product appearance] coated paper sheet

[product size] can be customized (consult customer service)

[guaranteequalityperiod] sealed storage for next 18 months

[scope of application] widely used in electronic materials, leather products, shoes and bags, handicrafts, clothing, cultural relics archives, etc.

Product Introduction

MICROGARDE®coated fiber desiccant is based on plant fiber as the carrier, and after soaking, drying, coating, cutting and other processes refined, convenient and practical, strong moisture absorption. And can be cut or punched into a variety of shapes and sizes, enabling the ordinary packaging structure, making it a functional packaging, is an ideal choice for many electronics, shoes and clothing products.

Technical Requirements

fiber sheet

|

Name |

moisture absorption rate25 ℃ RH20% RH50% RH80% |

thickness |

water content |

Appearance |

||

|

fiber sheet |

≧ 10% |

≧ 30% |

≧ 70% |

3mm |

≦ 5% |

clean and tidy surface printing clear handwriting |

Product Features

1. Material selection is reliable:selection of plant fiber as raw material, after testing, with tasteless, no corrosion, chemical stability and other characteristics, so that you can use peace of mind.

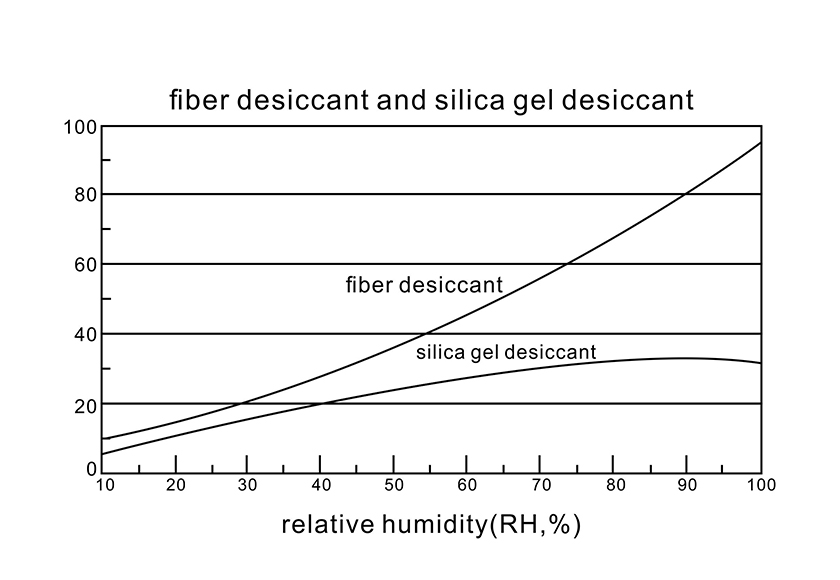

2. Continued effectiveness:MICROGARDE®film type fiber desiccant has a strong moisture absorption capacity, with the increase of humidity, moisture absorption is stronger, can continue to effectively prevent all kinds of goods damp mildew.

3. Personality cutting:MICROGARDE®film-coated fiber desiccant, with a thickness of only 1mm and a thin shape that does not occupy an area, can be individually cut or punched into various shapes and sizes, making it more convenient for you to use.

4. to map custom:MICROGARDE®film type fiber desiccant, shape like paper, the upper and lower are made of color PET film, not only beautiful and meet the needs of printed text customization;

Application Scenarios

MICROGARDE®fiber desiccant is widely used in electronic materials, leather products, shoes and bags, handicrafts, clothing, cultural relics archives and other items that need moisture-proof and mildew-proof.

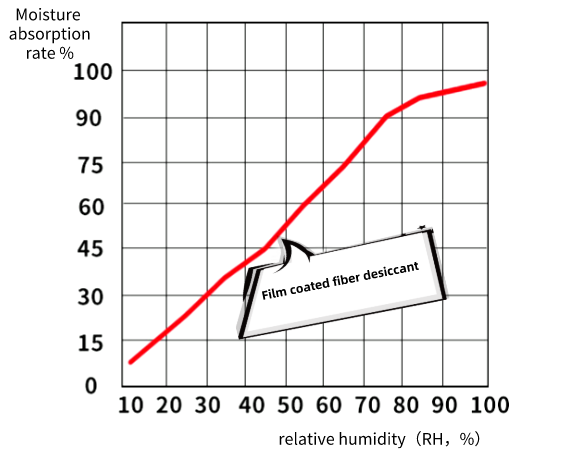

Moisture absorption curve

MICROGARDE® fiber desiccant moisture absorption curve display

data are laboratory test results, temperature:25 degrees Celsius, humidity 90%

moisture absorption contrast

moisture absorption rate

has more outstanding moisture absorption performance, and the fiber sheet changes from hard to soft after moisture absorption.

data are laboratory test results, temperature:25 degrees Celsius, humidity 90%

product customization

all of our desiccant products can be customized, consult customer service to choose suitable for your desiccant products!

Consultation Negotiation& rarr; Identify intent to cooperate→Determine raw material packaging materials→Determine prototype design→Proofing and Sending Samples→sign the contract→bulk production→shipment

tips:design samples can be provided by your company, but also by our company to help design, if you need to print your companyLOGO, please also provide brand proof.

Considerations

Desiccant storage use matters needing attention

I Storage:The desiccant must be sealed and stored in a cool, dry and chemical-free warehouse, isolated from the outside air, and will not be affected by the next use.

II Transportation:The desiccant should be handled with care during transportation to avoid abrasion of internal and external packaging. At the same time, it should prevent contact with acid and alkali substances, avoid sunlight, rain and snow, and prevent fire and moisture.

three use:

① The desiccant needs to be used under dry environmental conditions;

② Before use, check whether the sealing of the packaging container is good. For vacuum packaging products, check whether the vacuum bag packaging container is damaged. If there is an indicator silicone, the indicator silicone changes color before use. Ensure that it can be used under the above conditions;

③ After opening the packaging container, the desiccant should be used as soon as possible. According to the actual usage of the factory, the unused desiccant should be sealed and stored in time;

④ When using the desiccant, the desiccant bag should not be squeezed and rubbed, and the desiccant bag should not be thrown at will to avoid leakage and breakage of the desiccant bag..

Get full instructions for use

Browse Instructions for Use→